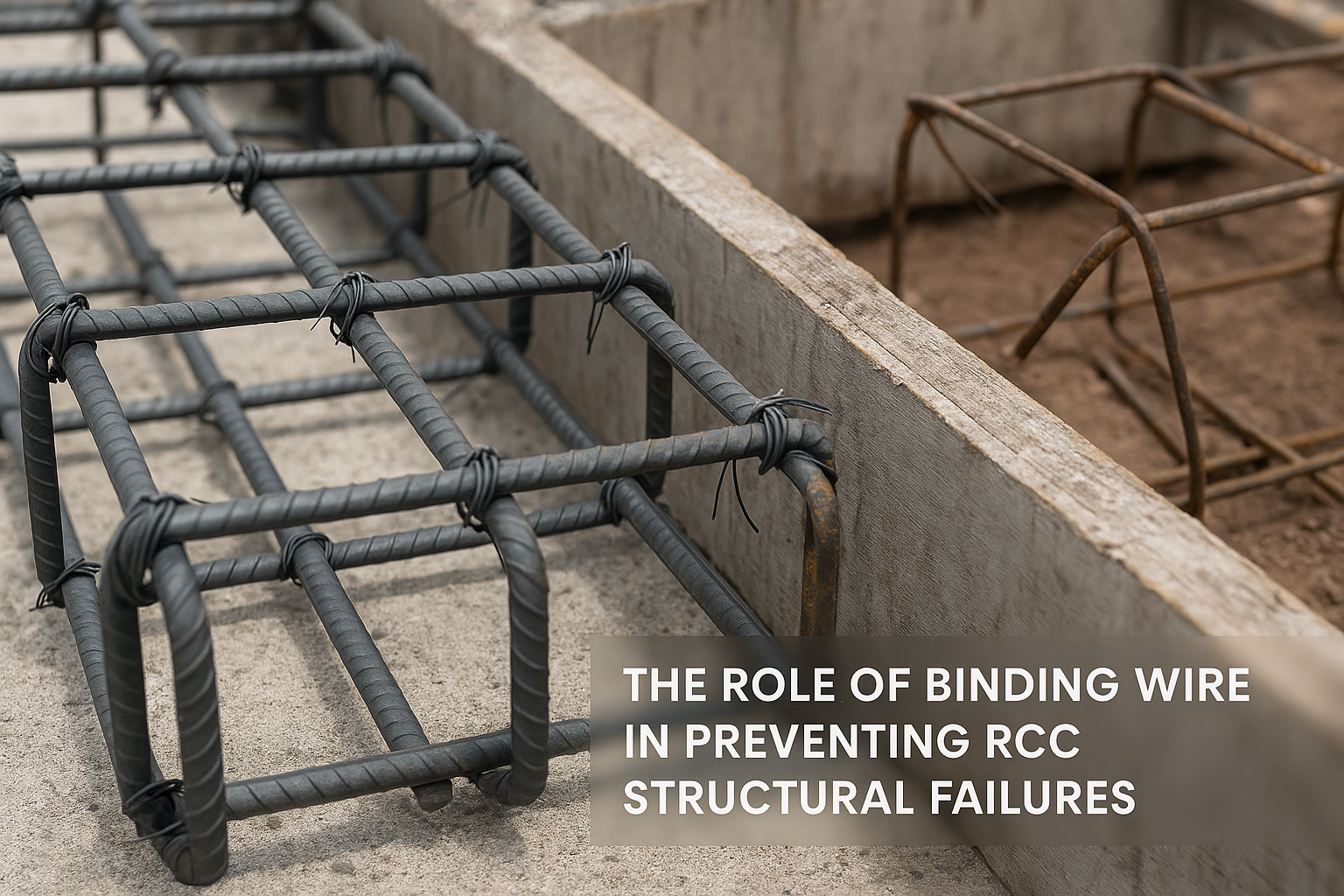

When it comes to RCC construction, everyone talks about TMT bars-and rightly so. But what often goes unnoticed is the small, almost invisible element that holds the entire reinforcement together – MS Binding Wire. Used for tying TMT bars into stable cages, binding wire ensures that the steel skeleton of a structure remains in its intended shape before and during concreting.

Yet, improper usage of binding wire can lead to structural failures, from minor cracks to dangerous load-bearing issues.

- Why Binding Wire Matters in RCC Frameworks

Binding wire for construction is not a load-bearing element, but it plays a vital role in keeping TMT bars in position until the concrete sets. Without proper tying:

- Rebars may shift during vibration

- Cage alignment can be lost

- Gaps can form, reducing structural strength

A contractor in Nagpur learned this the hard way when a poorly tied column cage shifted during concreting, leading to hairline cracks in the finished structure. Repair costs? Several lakhs – all because of weak binding wire work.

- The Correct Gauge & Strength Selection

Binding wire gauge impacts both workability and strength. Too thin, and it snaps during tying; too thick, and it becomes hard to twist.

APL Apollo SG recommends using 0.61 mm to 1.22 mm ductile and strong binding wire for most RCC applications.

✅ Ductility allows easy twisting without breakage

✅ Tensile strength holds bars in place even during high-frequency vibration

- The Right Technique for Tying TMT Bars

Improper tying is one of the most common site-level mistakes. Here’s what professional site engineers follow:

- Double-strand ties for major joints

- Maintain tight knots without over-twisting

- Use a consistent pattern across the cage

This ensures uniform load distribution and prevents movement during concrete pouring.

- Avoid Rusted or Substandard Binding Wire

Many small projects try to cut costs by using locally sourced, rusted binding wire. Not only does rust reduce strength, but it can also stain concrete and corrode nearby TMT bars. Always choose SG Strong Binding Wire for corrosion resistance and consistent quality.

Also read: The Role of MS Binding Wire in RCC Structures – Small but Mighty

- Linking Binding Wire to TMT Bar Durability

Improper binding wire use can indirectly lead to TMT bar cracks due to cage shifting and bending stress. That’s why it’s essential to coordinate binding wire work with the quality of TMT bars used.

Related post: Why TMT Bars Crack in Columns or Beams – Mistakes to Avoid on Site

- Live Case Scenario: How Proper Binding Wire Saved a High-Rise Project

In a commercial tower project in Pune’s Hinjewadi IT hub, engineers used APL Apollo SG Binding Wire to tie Fe 500D TMT bars for all shear walls and core columns. Despite high concrete vibration levels during pouring, not a single cage shifted – ensuring perfect alignment and zero cracking in finished members.

The cost of using premium binding wire? Negligible. The savings in repair and delay costs? Massive.

Conclusion: Small Wire, Big Responsibility

The strength of your RCC framework is only as good as the weakest component. While TMT bars provide the backbone, MS Binding Wire ensures they remain in place to do their job.

Choose APL Apollo SG Binding Wire for your next project – because structural safety starts with the small details.

📌 You May Also Like to Read