Introduction

India’s construction sector is on a record-breaking trajectory, projected to hit $1.4 trillion by 2030 (Source: IBEF). At the center of this growth lies structural steel—a material that defines the strength, durability, and flexibility of modern infrastructure.

If you’re a builder, contractor, engineer, or distributor, understanding structural steel products and their suppliers in India is not just useful—it’s essential for project success. Whether it’s TMT bars for residential buildings, hollow sections for industrial plants, or beams for bridges, steel determines both safety and cost-effectiveness.

As a Structural Steel Product Manager with over 12 years of experience, I’ve witnessed firsthand how choosing the right steel supplier can make or break a project timeline. In this guide, we’ll cover:

The different types of structural steel products available in India.

Market trends and pricing insights for 2025.

How to evaluate and select trustworthy suppliers.

A rundown of top steel suppliers in India.

Case studies and future trends shaping the industry.

A practical buying guide for contractors and distributors.

What Are Structural Steel Products?

Definition & Uses

Structural steel refers to engineered steel forms manufactured to specific standards for construction. Its key properties include:

High strength-to-weight ratio – makes it ideal for high-rise buildings.

Durability – resistant to wear and tear in industrial environments.

Versatility – customizable into beams, rods, sheets, or sections.

Common Product Categories

Steel Beams (I-beams, H-beams): Used in bridges, commercial complexes.

Steel Angles & Channels: For trusses, frames, and light construction.

Plates & Sheets: Essential for shipbuilding, flooring, and fabrication.

Pipes & Hollow Sections: Popular in metro projects, warehouses, and solar structures.

Rebars & TMT Bars: Provide tensile strength in RCC construction.

Fasteners & Connectors: Bolts, screws, rivets that hold everything together.

Example: A high-rise tower in Mumbai might use Fe 550D rebars for foundation strength, while APL Apollo hollow sections form the framework of its rooftop solar canopy.

Market Overview of Structural Steel in India

Industry Growth & Data

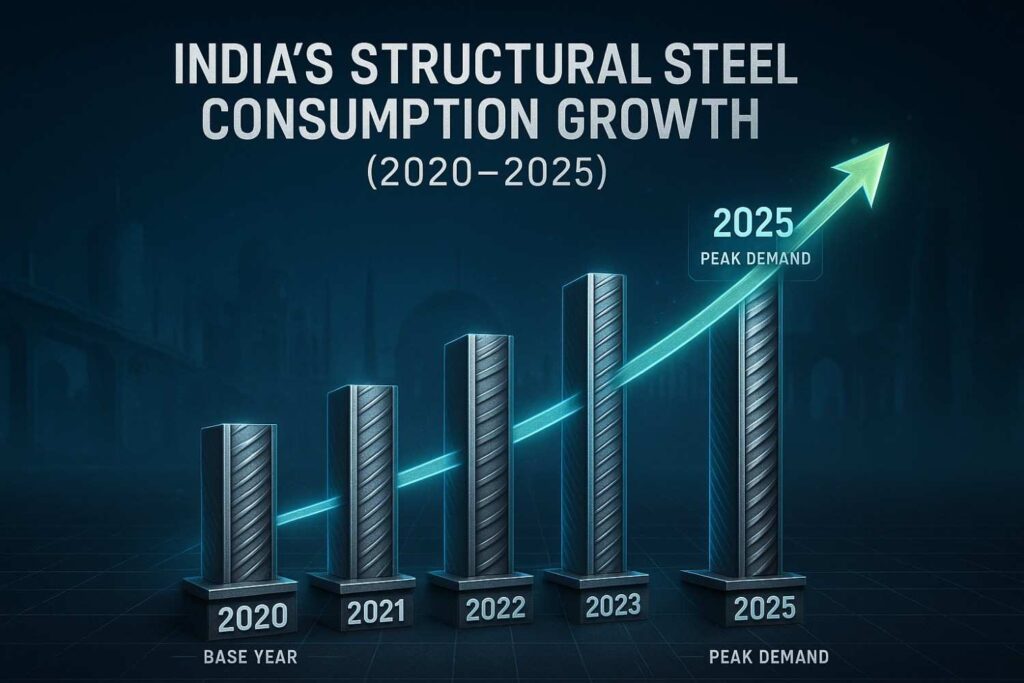

India is now the second-largest steel producer in the world (Source: World Steel Association), producing over 125 million tonnes annually. Structural steel accounts for a major share, with demand growing at a CAGR of 6–7% (2025 forecast).

Key demand drivers:

-

Rapid urbanization → housing projects.

-

Government push → Smart Cities, Gati Shakti infrastructure plan.

-

Renewable energy → wind turbines, solar structures.

Pricing Trends (2025 Update)

Steel prices are dynamic, influenced by raw material costs, global demand, and logistics.

TMT steel price per kg in India (2025): ₹55–₹75.

-

16mm steel bar price: ₹800–₹1,050 per piece.

-

Structural hollow sections: ₹65–₹85 per kg.

How to Choose the Right Structural Steel Supplier in India

Supplier Evaluation Criteria

When selecting a supplier, look beyond just pricing. Consider:

✅ Certifications: BIS, ISO 9001.

✅ Product Range: Wide categories (beams, TMT, pipes).

✅ Logistics Capability: PAN-India distribution network.

✅ After-Sales Support: Technical advice, replacement policies.

✅ Customization: Ability to provide tailor-made sizes/grades.

Red Flags to Avoid

❌ Suppliers without transparent pricing.

❌ Lack of official certifications.

❌ Delays in fulfilling bulk orders.

Quick Supplier Checklist:

Check past projects.

Ask for material test certificates.

Compare credit/payment terms.

Top Structural Steel Suppliers in India

Leading Brands & Manufacturers

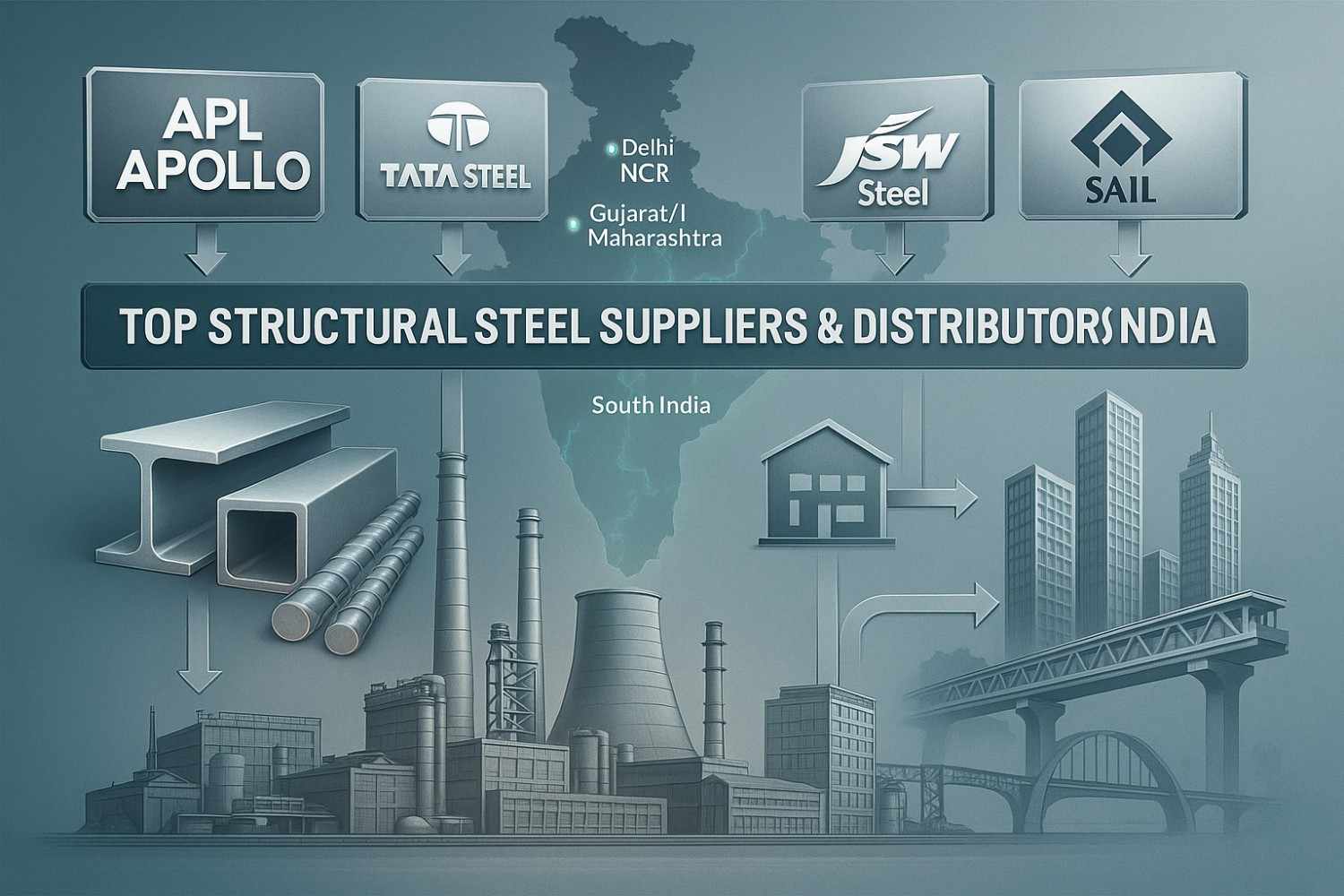

-

APL Apollo Tubes Ltd.(SG MART LIMITED)

-

India’s largest producer of structural steel hollow sections.

-

Known for innovative steel solutions for infra & real estate.

-

Wide dealer network across India.

-

-

Tata Steel

-

Legacy steel producer with international reach.

-

Supplies beams, plates, rebars, and more.

-

-

JSW Steel

-

Strong presence in construction steel.

-

Offers energy-efficient, eco-friendly products.

-

-

SAIL (Steel Authority of India Ltd.)

-

State-owned giant.

-

Key supplier for government projects (railways, bridges).

-

-

Jindal Steel & Power

-

Popular for power, energy, and industrial applications.

-

Regional Distributors & Dealers

-

Delhi NCR → strong network for infra projects.

-

Gujarat & Maharashtra → industrial hubs.

-

South India → real estate boom.

Case Studies: Structural Steel in Action

Metro Rail Expansion (Delhi & Mumbai): Used APL Apollo hollow sections for station roofing and support frameworks.

Renewable Energy Projects (Tamil Nadu & Gujarat): Wind turbine towers used high-strength beams and plates.

Smart City Housing: Contractors opted for Fe 500D rebars for earthquake resistance.

💡 My Experience: During a 2022 Gujarat project, sourcing Fe 500D rebars from a reliable supplier reduced construction delays by 12%. That’s the real impact of supplier trustworthiness.

Trends Shaping the Future of Structural Steel in India

Sustainability & Green Steel

Push for low-carbon steel by 2030.

Use of scrap recycling in manufacturing.

Digital Supply Chain

AI-driven demand forecasting.

Real-time order tracking.

Product Innovation

Prefabricated steel sections for modular buildings.

Advanced coatings for rust & fire resistance.

External Links: McKinsey steel insights, Ministry of Steel India reports.

Buying Guide for Contractors & Builders

Checklist Before Ordering:

Verify grade (Fe 500, Fe 550, Fe 500D, Fe 550D).

Compare prices (₹/kg).

Ask for mill test certificates.

Confirm delivery timelines.

Negotiate bulk order discounts.

Tips:

Order buffer stock for mega-projects.

Build long-term relationships with suppliers for better credit terms.

Conclusion

Structural steel is more than just a material—it’s the backbone of India’s infrastructure journey. From beams and hollow sections to rebars and sheets, choosing the right supplier ensures quality, safety, and timely project delivery.

As we’ve seen, India’s market is dominated by leading players like APL Apollo, Tata, JSW, SAIL, and Jindal, but success depends on aligning supplier capacity with your specific project needs.