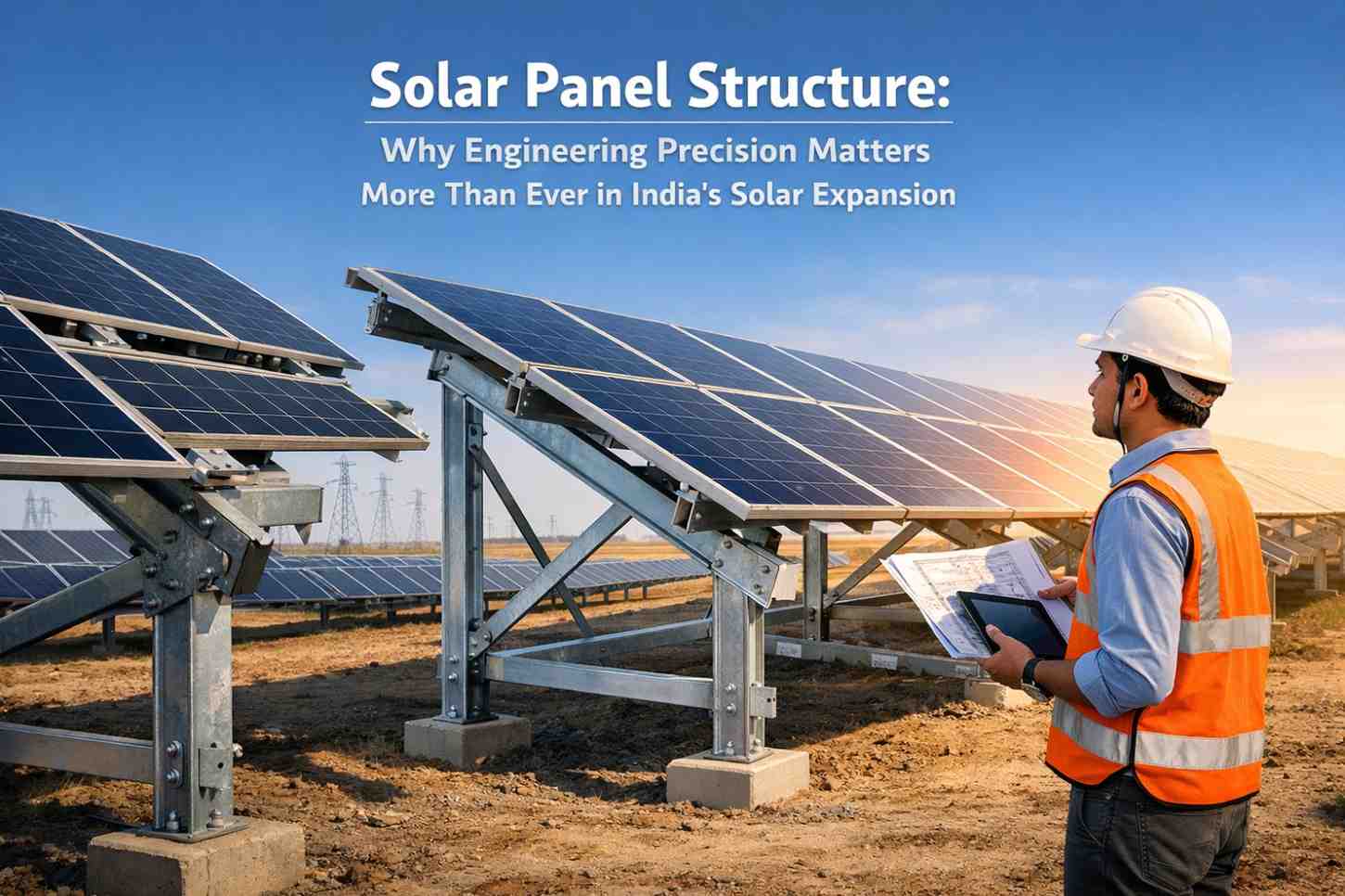

India’s solar capacity is scaling faster than any other renewable segment in the country’s energy mix. From utility-scale solar parks in Rajasthan and Gujarat to rooftop installations across industrial zones, one component quietly determines the success or failure of every project — the solar panel structure.

While solar panels and inverters receive most of the attention, experienced EPC contractors and developers know that the real backbone of a solar plant is its mounting structure. In 2025, as wind loads, terrain challenges, and long-term asset performance come under scrutiny, the conversation around solar structure design and manufacturing quality has become more critical than ever.

The Role of Solar Panel Structures in Project Performance

A solar panel structure does far more than simply hold modules in place. It directly influences:

-

Load distribution across terrain

-

Resistance to wind, seismic, and thermal stress

-

Alignment accuracy for optimal energy yield

-

Long-term maintenance and corrosion performance

In poorly designed systems, even premium solar modules underperform due to structural misalignment or deformation over time. This is why developers increasingly evaluate solar module mounting structures as a technical investment — not a commodity purchase.

Why Structural Engineering Is Now a Priority in Solar Projects

1. Higher Wind & Climate Risk Zones

India’s expanding solar footprint now includes coastal regions, desert belts, and high-wind corridors. These environments demand precisely engineered solar structures capable of maintaining stability across decades.

2. Longer Asset Life Expectations

With solar projects designed for 25+ years, the structure must endure continuous exposure to heat cycles, humidity, dust, and mechanical stress. Material fatigue and corrosion resistance are no longer optional considerations.

3. EPC Accountability & Bankability

Financiers and insurers increasingly assess mounting structures during technical due diligence. Poor structural documentation or inconsistent manufacturing can delay approvals or increase insurance premiums.

Fixed-Tilt vs Adjustable Solar Structures: What the Market Is Choosing

While tracker systems attract attention, fixed-tilt solar panel structures remain dominant across India due to:

-

Lower capital cost

-

Faster installation

-

Reduced maintenance complexity

-

Better suitability for rooftop and industrial projects

This has led to increased demand for robust fixed-tilt solar module mounting structures, engineered for region-specific wind loads and soil conditions.

What Differentiates Reliable Solar Structure Manufacturers

Not all solar structure manufacturers operate at the same engineering standard. In recent years, experienced developers have started prioritizing manufacturers who demonstrate:

In-house design and load calculation capability

High-precision steel fabrication

Consistent galvanization or coating quality

Documented testing and compliance standards

This shift reflects a maturing solar ecosystem — where structural reliability directly influences ROI.

Steel Quality: The Hidden Variable in Solar Structure Longevity

The performance of a solar structure is only as strong as the steel behind it. Inferior steel can lead to:

Micro-cracking under thermal stress

Premature corrosion

Alignment drift affecting panel efficiency

Modern solar projects increasingly prefer high-strength, precision-processed steel structures — a trend influenced by India’s evolving steel manufacturing capabilities and stricter project warranties.

Why Documentation & Transparency Matter

Developers today expect clear technical documentation, including:

Structural drawings and load calculations

Installation guidelines

Maintenance considerations

This transparency improves on-site execution and reduces long-term risk — especially in large-scale deployments where structural failure can impact thousands of modules.

Solar Structures in the Broader Energy Transition

As India moves toward its renewable targets, solar mounting systems are no longer secondary components. They are part of a critical infrastructure ecosystem supporting grid stability, energy security, and decarbonization goals.

From industrial rooftops to megawatt-scale solar parks, the conversation is shifting from “lowest cost” to “best lifecycle performance” — and the solar panel structure sits at the center of that shift.

Final Perspective: Building Solar for the Long Term

The next phase of India’s solar growth will be defined not just by how many panels we install, but how intelligently we support them.

For EPCs, developers, and infrastructure planners, investing in well-engineered solar structures is no longer a design preference — it is a strategic decision that determines project resilience, efficiency, and credibility.

As the industry matures, solar structure engineering will continue to separate short-term installations from truly sustainable energy assets.

Reference (Technical Brochure)

Reference (Technical Brochure)

For those evaluating structural design parameters and manufacturing approaches in detail, technical catalogues such as:

APL Apollo Sun Steel Solar Mounting Structure Catalogue (PDF)

provide insight into current engineering practices and material specifications.

Pingback: Solar Structures in 2025: Installation Challenges & What EPCs Must Fix

Pingback: How EPCs Redesign Solar Structures for 25-Year Reliability