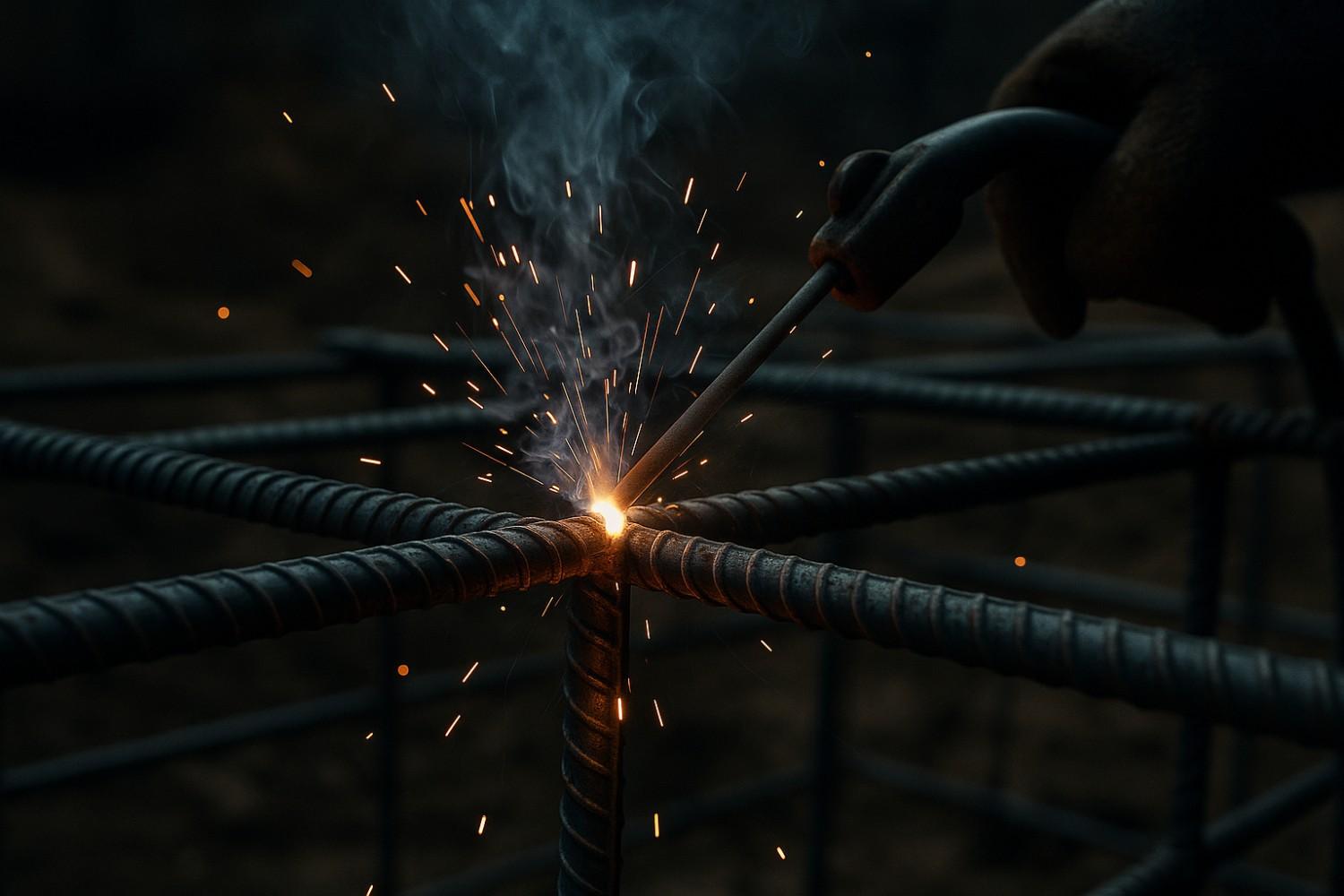

In modern construction, steel reinforcement forms the backbone of strength – but it’s the connections that define its reliability. While we often focus on high-grade TMT bars and precise tying using MS Binding Wire, one essential yet overlooked component is the humble welding rod. Especially in larger RCC and structural steel frameworks, welding rods – particularly MS Welding Electrodes – are used to create strong, rigid joints where bar overlaps, anchor plates, or steel cages meet.

So, how do these small electrodes make such a big impact on your structure? Let’s explore.

🔩 What Are Welding Rods and Where Are They Used in RCC Construction?

Welding rods (or electrodes) are coated metal wires used to join two steel components through arc welding. In construction, especially for:

- Fixing TMT bars that require precise angular connections

- Welding additional structural members in beams, columns or slabs

- Modifying steel cages when pre-tied assemblies need on-site adjustment

These rods are indispensable.

Imagine a scenario: You’re constructing a commercial complex with customized steel frameworks for cantilever projections. The steel fabricator uses SG Binding Wire for preliminary cage formation. But to ensure that TMT bars stay perfectly positioned during concrete pouring, strategic welding is performed at key junctions – using reliable MS Welding Rods.

🔧 Why Joints Matter: The Integrity of a Structure Lies in Its Connections

Even the highest grade of TMT bars can underperform if their connections aren’t structurally sound. Site-welded joints help:

- Prevent movement of steel during concrete pouring

- Strengthen complex junctions like beam-column intersections

- Support bar cages in cantilever and basement raft constructions

The use of poor-quality welding rods, on the other hand, can lead to brittle welds, corrosion-prone joints, or even undetectable cracks – compromising structural safety.

🔥 APL Apollo SG MS Welding Electrodes – Built for Strength, Designed for Site Efficiency

At SG Mart Limited, we offer Mild Steel Welding Electrodes (APL Apollo Agni series), trusted by contractors and site engineers across India.

Key Features:

- Smooth weld finish with minimal spatter

- Quick arc initiation – perfect for time-critical jobs

- Sizes available: 2.5 mm, 3.15 mm, and 4.0 mm

- Suitable for both flat and overhead welding applications

These electrodes are engineered for practical job-site challenges, providing consistent performance even during long welding runs.

🔗 Site Story: From Fabrication Shed to Foundation Raft

In a recent G+5 residential project in Ghaziabad, the civil contractor faced issues with prefabricated cages shifting during pouring. While SG Binding Wire did its job securing the initial form, it was the site-welding using APL Apollo Agni rods that locked the joints into place. The result? Zero shifting, perfectly aligned cages, and a complaint-free inspection.

Just like tying bars with MS Binding Wire ensures cage accuracy, proper welding joints ensure long-term stability. For more on cage formation, read:

→ Binding Wire Ensures Proper Cage Formation

🧱 Combine It Right: TMT Bars + Binding Wire + Welding Rods

Every material plays its part:

- Use APL Apollo SG TMT Bars (Fe 500D / Fe 550D) for strength and ductility

- Use SG Binding Wire for precise cage formation

- Use MS Welding Electrodes for permanent, reinforced connections

They’re not alternatives – they’re a team.

🛠️ Learn how construction sites ensure rebar quality → Read: How TMT Bars Are Tested

📞 Contact or Dealer Inquiry Page

Get in touch with our team or find a distributor → /contact/ or /dealers/

Pingback: Fasteners in India for RCC & Steel | APL Apollo SG

Pingback: Steel Frame Fasteners in India | Bolts, Nuts & Anchors for RCC Construction

Pingback: Fe 500 vs Fe 500D TMT Bars – Which Is Best for Construction?

Pingback: Top 10 TMT Bars in India 2025 | Best Construction Brands

Pingback: India Steel Demand 2025 – Impact on TMT Bars & RCC